Reverse Engineering Project | Nunley’s Carousel

Bringing a piece of Long Island History back to life with reverse engineering.

At Reno Machine, most of our machining projects involve high-precision aerospace components, but every now and then, a job comes along that’s truly one-of-a-kind. We recently had the privilege of helping restore a vital piece of Nunley’s Carousel Museum at the Long Island Children’s Museum.

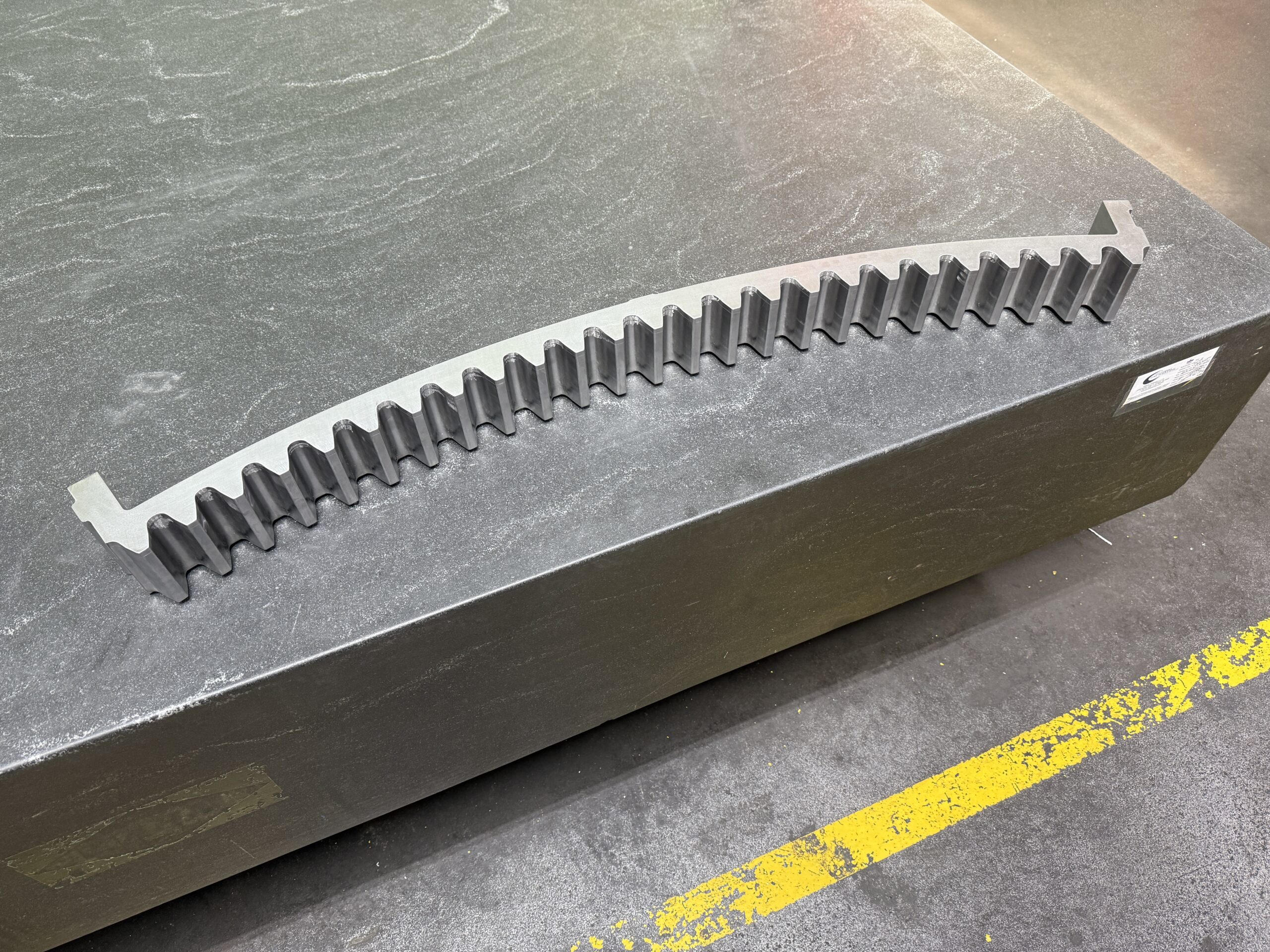

When we received the damaged 100+ years old carousel part, there were no original prints or drawings to reference. This carousel had been delighting riders long before CAD files existed, which meant we had to get creative.

Our skilled team used reverse engineering to study the damaged component, determine its exact specification, and model a precise replica. From there, we machined a brand-new part that will allow the carousel to spin once again, bringing joy to generations to come.

While this wasn’t our typical project, it still required the same expertise, attention to detail, and craftmanship that we bring to every job. Reno Machine specializes in large-format CNC machining, including complex 3- to 5-axis work, and we serve customers throughout New England and beyond. Whether it’s a cutting-edge aerospace assembly or a century-old carousel, we take pride in delivering parts that keep the world (and rides) moving. Contact us to turn your project into reality.

Learn more about this project: https://www.newsday.com/long-island/nassau/nunleys-carousel-reopens-cmagsasd