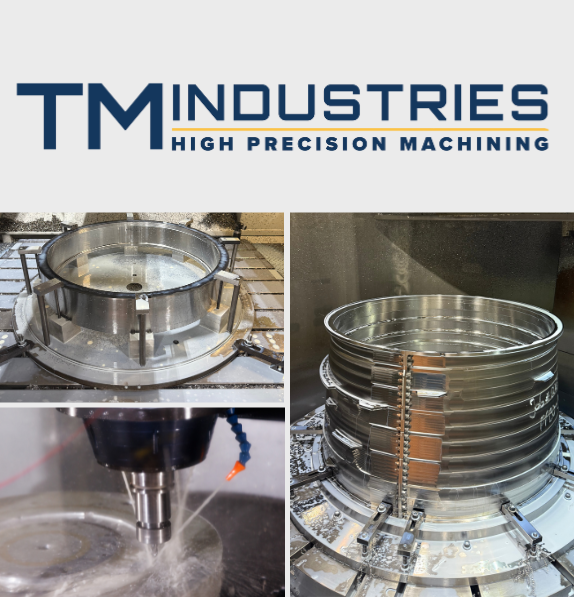

TM Industries, LLC

High Precision Machining

High Precision Machining

TM Industries, LLC specializes in high precision contract machining and concurrent engineering of medium-to-large components for the power generation industry. Prior to Reno Machine ownership, TM Industries operated successfully for 62 years with core competencies including 3, 4, 5, 6 and 7 axis milling and large diameter turning.

With a tenured workforce experienced in machining, engineering and programming complex components, TM Industries, LLC is dedicated to providing the highest quality products and service levels in the industry. Our ability to handle and machine very large components as well as technical expertise differentiates us from our peers.

Capabilities:

- 36”-240” product size

- Large scale machining

- Up to 20 ft in diameter

- Up to 15 ft in height

- Up to 35 feet in length

- Up to 66 tons

- ISO 9001:2015 and AS9100:2016 certified

- Electric Boat & BAE Supplier Gold

Facilities

Inside TM Industries LLC’s 55,000 square foot state-of-the-art facility are machining and support equipment for large-part machining, including CNC controls, automatic tool changers, and multiple live spindle machines. Additionally, the Main Room cranes have a capacity of 30 and 66 tons.

Key Customers

TM Industries, LLC has built a foundation of trust from aerospace and marine companies, including PCC, BAE Systems, GE Aerospace, General Dynamics Electric Boat and Pratt & Whitney.

Together, with Reno Machine, TM Industries services additional customers in the aerospace, defense, and R&D industries, including Sikorsky, Collins Aerospace and others.